Baltimore Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma has been around for more than two decades, and no, it is not a myth. This method has been a valuable addition to any career path as more companies and businesses find it valuable for continuous improvement and growth. What makes it so valuable? It is important to review the history of Lean Six Sigma if you want to understand its usefulness and why you are missing a big chance if you don’t learn it. At Lean Six Sigma Curriculum for Baltimore High School Students of Maryland, we will give you a quick but complete overview of the methodology’s past and ensure you get started with the history that takes us to what LSS is today.

Before you rush to obtain training or certification, it is important to do your research. It will allow you to understand the benefits this method has for companies and why you should be considering it in your own company or for your personal growth as a student or professional.

This will allow you to take your time and make informed decisions about whether or not this is right for you. However, here’s a spoiler: 6 Sigma is always a good option.

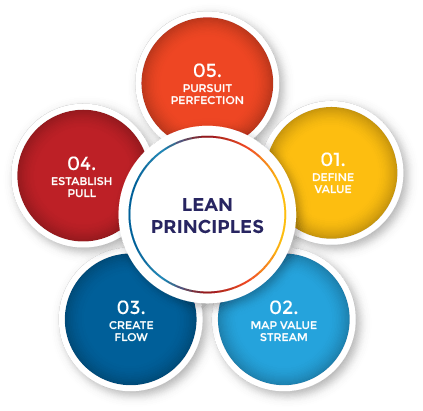

This method was originally created to help companies prioritize customers and increase efficiency to improve earnings.

The methodology can reduce costs and eliminate waste if used correctly. You can use it to succeed in other areas of life. Practitioners have shown that they can boost processes and reduce steps in their projects, saving time and money.

This approach accomplishes all of the above and improves customer satisfaction. It also reduces lead time for companies.

It is secondly based upon the collective knowledge and experiences of all parties. Implementation should only be possible when certified practitioners have been involved. Companies who want it to work should be taught it, not just implemented without providing context or sharing knowledge.

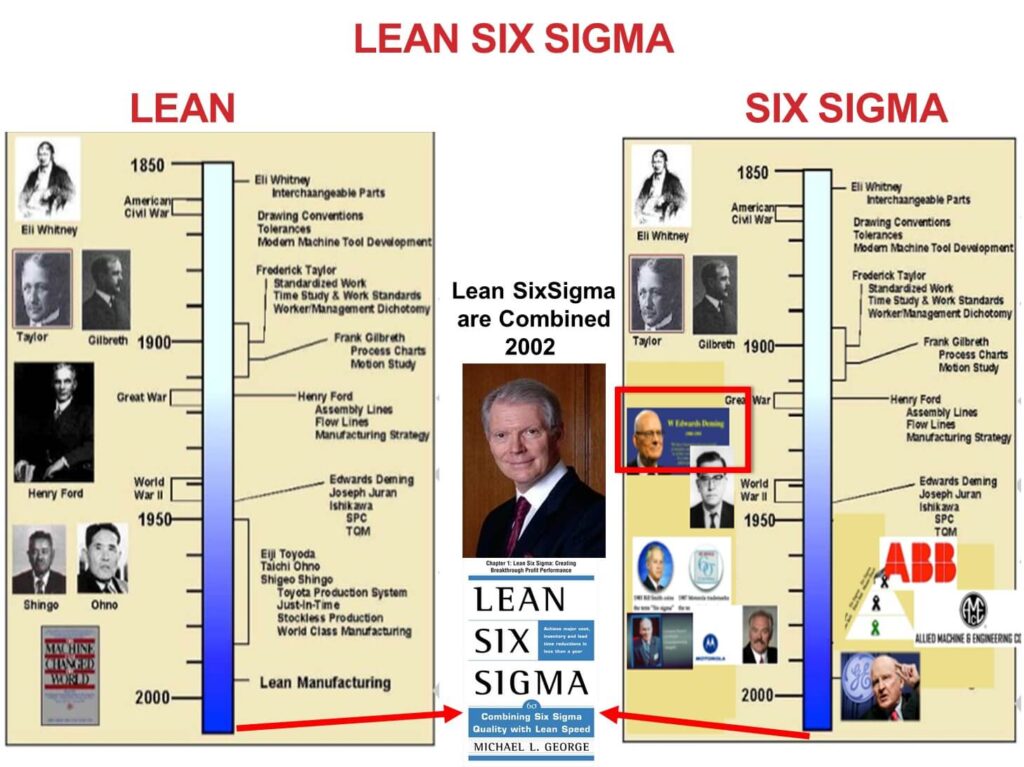

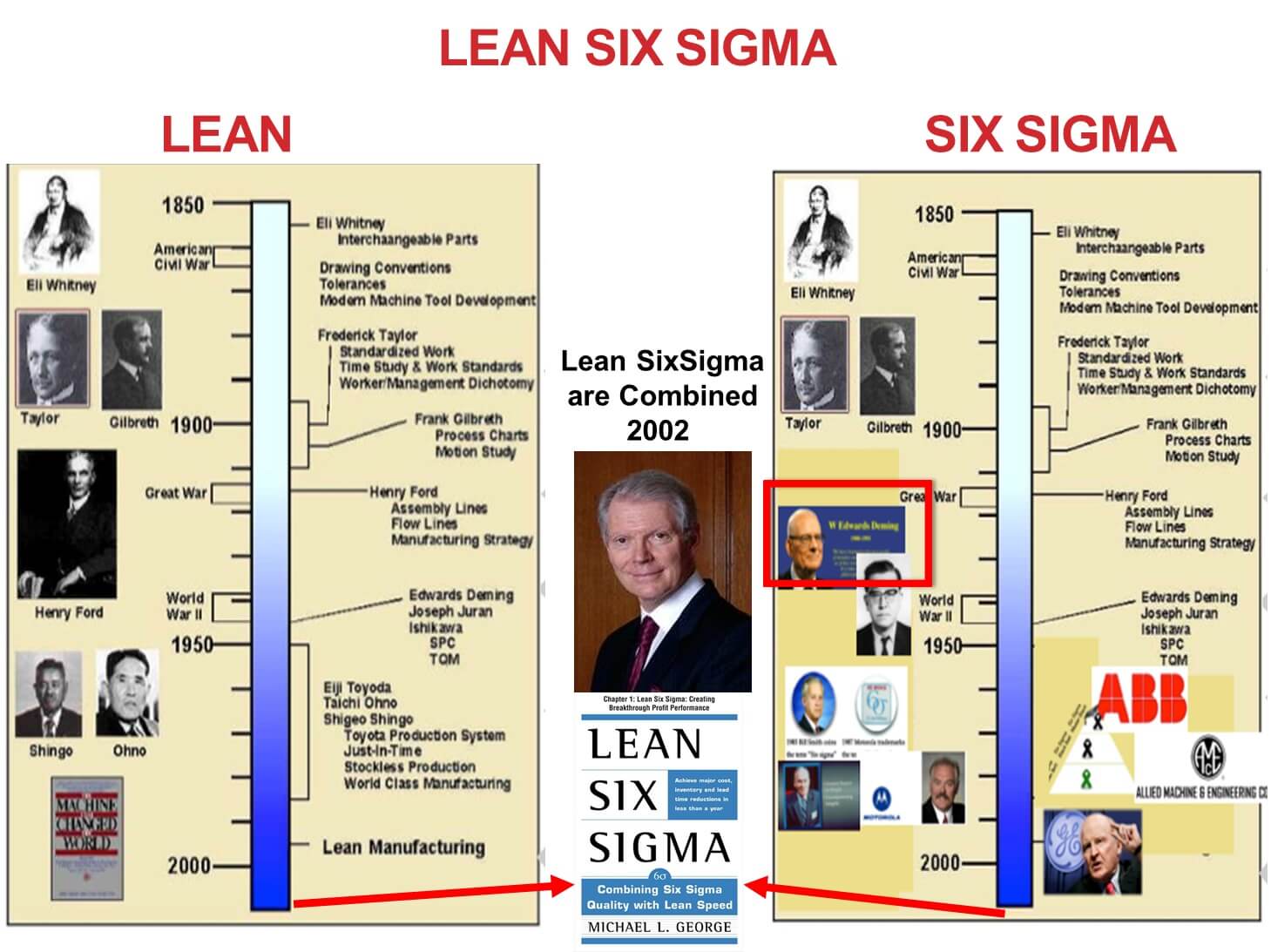

Let’s now focus on the facts: LSS was born from the combination of Lean & 6 Sigma while still adhering to its own principles and adding more value.

The Beginning of a Game-Changing Methodology

Before you can implement Sigma’s founding principles and logic in your business or personal life, it is important to understand them fully.

LSS may have its roots in the Japanese industry, or this is what most people believe since, in the 80s, American companies were competing with Japanese companies and their excellent products thanks to the implementation of their Kaizen methodology.

The methodology and more adaptations are the reason Japanese industries were able to produce high-quality products that satisfied customers, making them one of the most successful companies and industries in the 80s.

What does this mean for LSS? LSS was established to help American companies remain competitive and at the top of their game during these years, and for it, it took several principles from different methods.

Lean was first introduced in the 1940s. 6 Sigma, however, dates back to the 1980s.

Toyota developed Lean manufacturing in the late 1940s as a way to reduce non-value-adding activities.

Lean teaches employees that they must be involved in making organizational changes to foster excellence. To ensure happiness, everyone must be able to learn and improve continuously.

Toyota Production Systems (TPS) was the first company to use Lean. This company was founded by Japanese Taiichi Ohno, which is why many believe LSS is Japanese. This same method was used in Henry Ford’s Innovations and Business Process Redesign.

Six Sigma, which is a data-driven methodology, will be the next topic. In its core concept, Six Sigma is distinct from Lean. Motorola developed the method, and General Electric successfully used it in the 1980s.

Six Sigma is a process improvement tool that professionals and experts developed to make sure every process is controlled and problems are identified and resolved.

Its structure is based on the DMAIC option: Define, Measure, Analyze, Improve, Control. This is important for manufacturing and other industries because it allows them to automate their processes and prevents them from slowing down. Each step can be optimized instead and ensures problems are identified and solved.

Lean Six Sigma: What Are the Differences Between Individual Methodologies?

This was designed to allow American companies to compete with Japanese manufacturers. This is a combination of the two. However, the term “combination” reduces the potential for LSS.

American industries are today at the forefront of innovation, waste reduction, and employee participation, thanks to LSS. They can thrive and remain ahead of the curve because of this.

Sigma is not limited to products and services. New industries and fields have realized this over the past decade.

Schools and educational institutions can create systems that are more efficient and, therefore, easier to use. Students can also learn LSS to help them gain valuable skills and be ahead of their peers when they apply for jobs.

Lean Six Sigma can be a great way for you to get involved in today’s world. The principle of continuous improvement will not change

, no matter where it is implemented.

Essentially, it is about how LSS fills the gaps in the methodologies and ensures that anyone who implements it can achieve all the expected results while focusing on other areas for improvement.

At Lean Six Sigma Curriculum Pros of Baltimore, we can assist with certification and training to help you understand and appreciate the beauty of Sigma.

Contact us, and we’ll teach you everything, even more history.